Versa Products designs and builds pneumatic valves and accessories that outperform and outlast all others. We offer customized and standard solutions for the industrial, valve actuation, mobile, process control, and oil and gas markets.

Versa's extensive variety of directional control valves is comprised of seven distinct series, constructed from three types of material – aluminium, brass, and 316 stainless steel. These valves may be actuated by solenoid, pilot, manual or mechanical actuators and are manufactured to ISO 9001 standards, with many meeting SIL 3 capability.

Choose Versa for unsurpassed reliability.

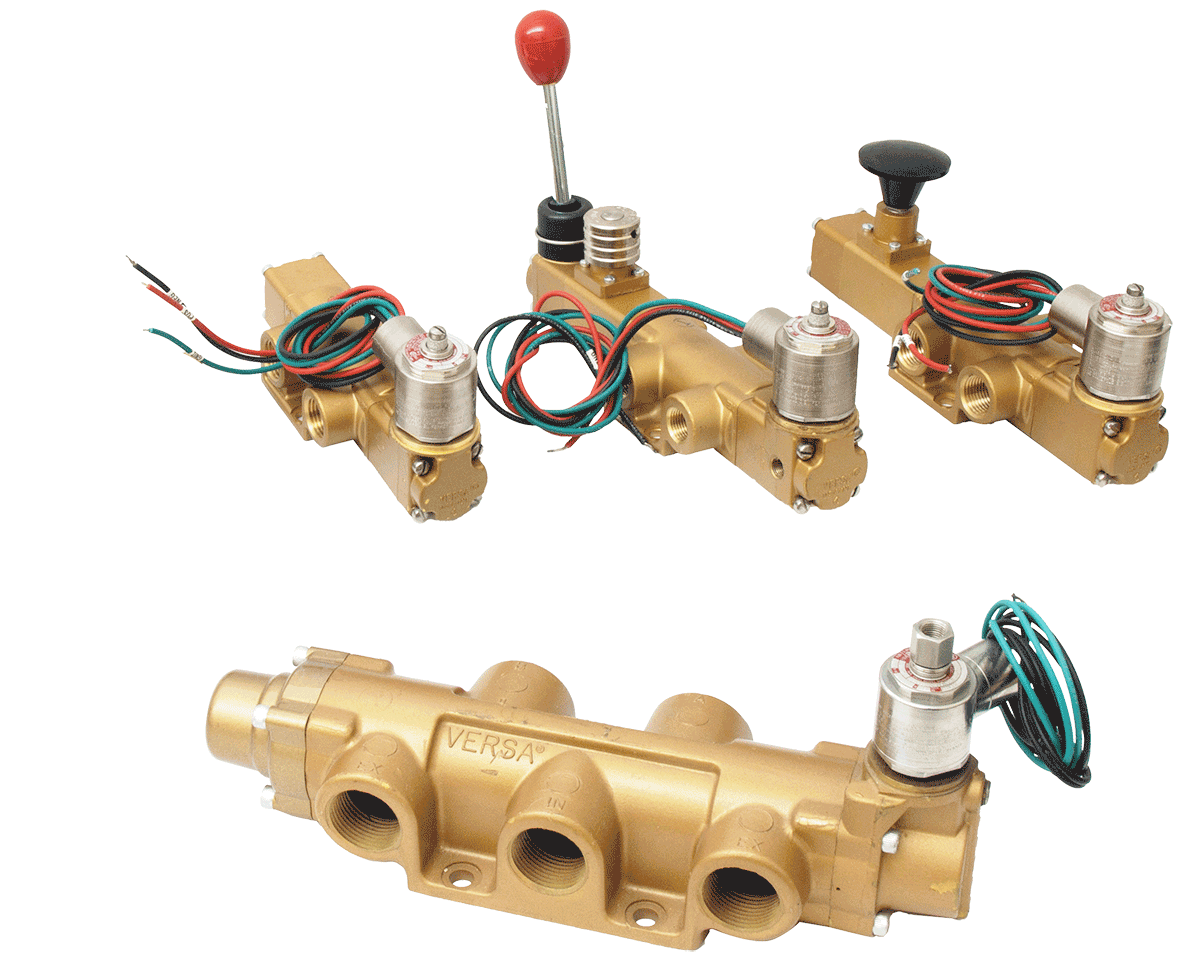

V & T Series Brass

Series “V” valves are designed for the control of pneumatic pressures from partial vacuum to 200 psi (14 bar). Series “T” valves are designed for the control of hydraulic pressures 0 to 500 psi (35 bar). Their maximum media temperature is 130°F (55°C). For practically all pneumatic, and for many low pressure hydraulic directional control applications there is a Versa Valve made for trouble-free performance under the most exacting conditions. Integrity of design makes Versa Valves adaptable to a maximum number of applications with a minimum of components. This is possible through the modular approach to valve construction, which allows valve bodies and actuating devices to be interchanged end for end and valve for valve in many cases.

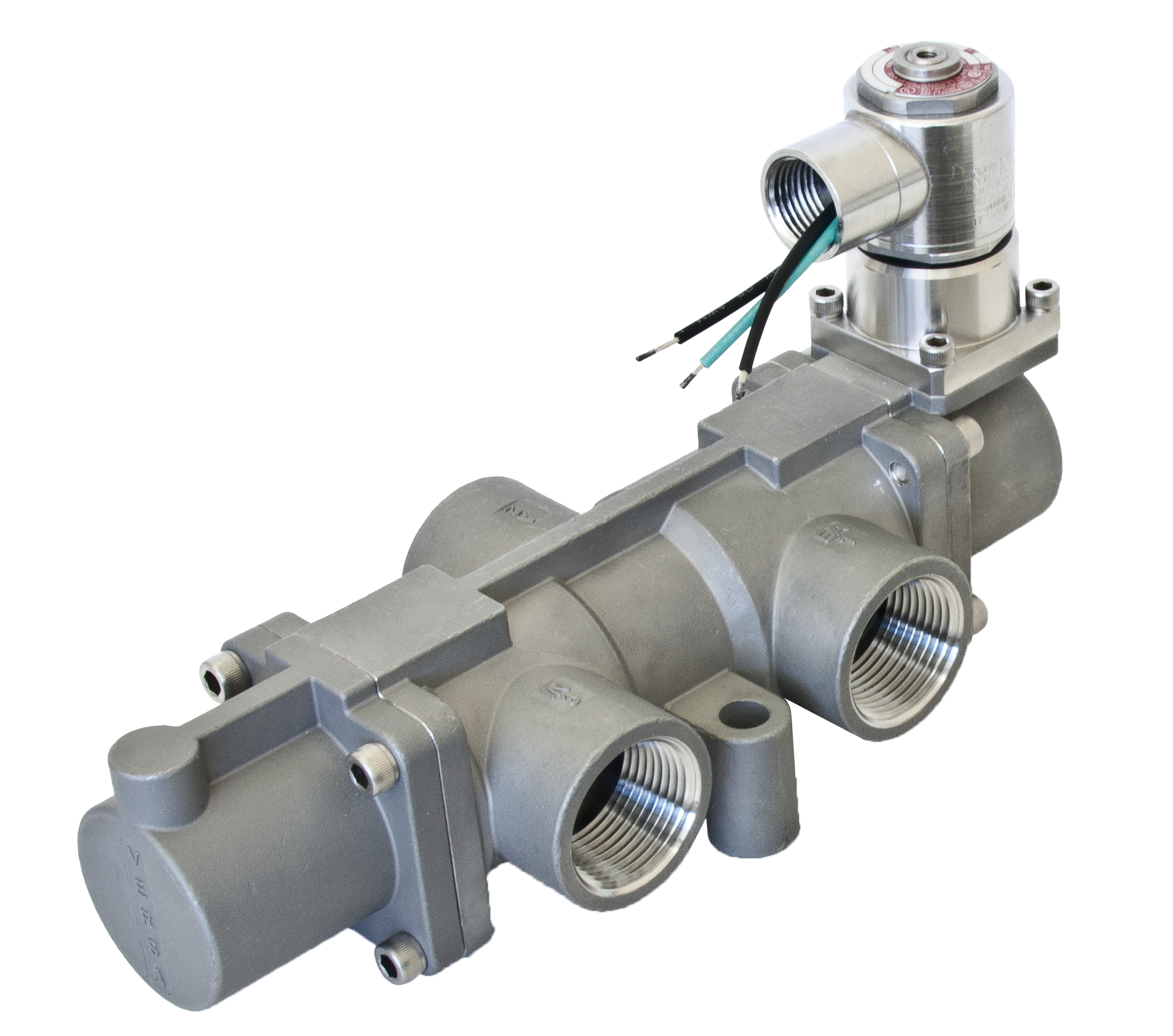

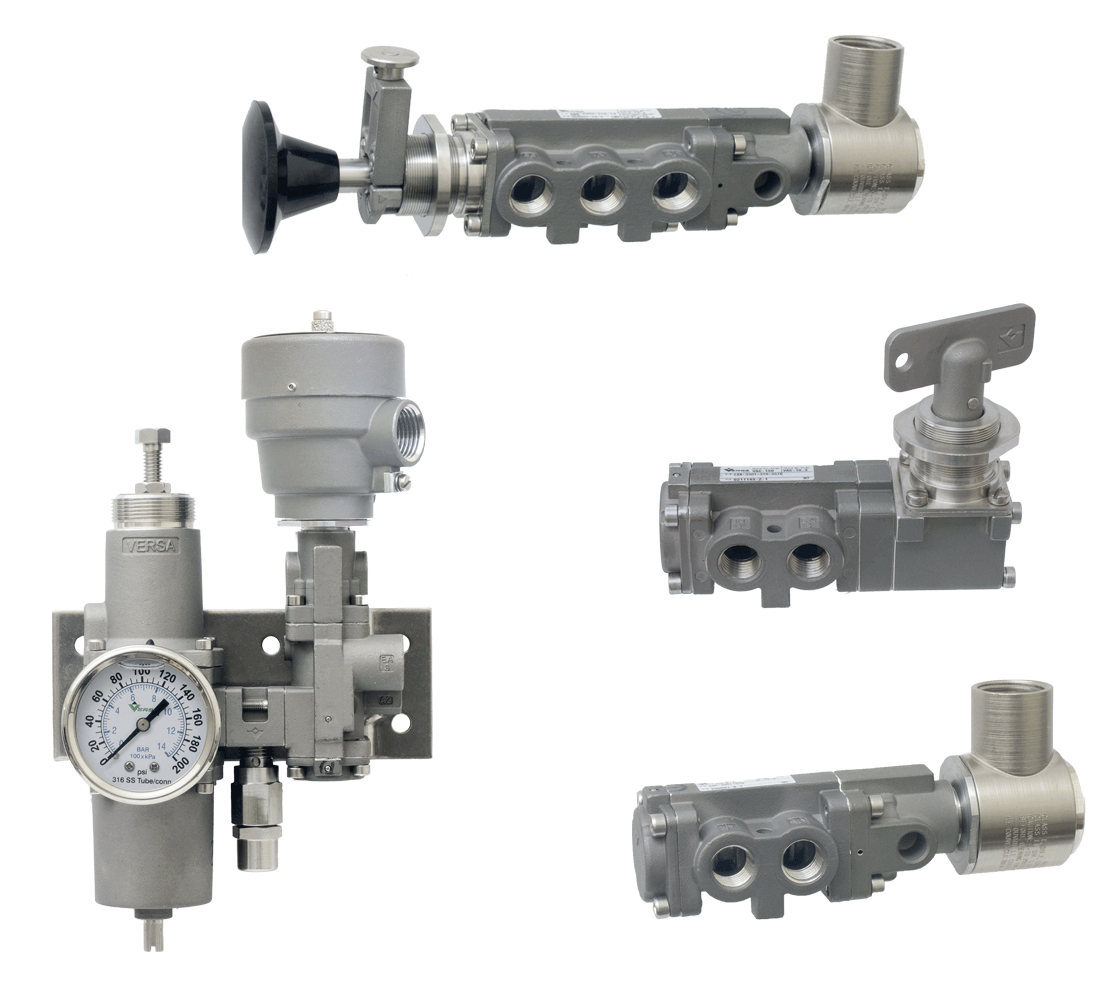

V-316 Stainless

The V-316 Valve Series provides a full range of control valves suited to the most demanding of applications. Ruggedly constructed, both internally and externally, of stainless steel, these valves are able to withstand the physical abuse of corrosive environments and controlled media. A modular design concept utilizing three basic sub-assemblies: a Body Assembly and two Actuator Assemblies (active or passive), simplifies circuit planning while affording almost unlimited combination possibilities. Port sizes are 1/4”, 3/8”, and 1/2” NPT in 2 and 3-position, three-way (3/2, 3/3), and four-way (5/2 and 5/3) styles. A 1” NPT is available as 2-position, three-way (3/2) and four-way (5/2). Actuation types include manual (hand lever, palm button, latching detent & manual reset), pilot (pressure pilot, diaphragm pilot, “air-latch” pilot), and solenoid-pilot (including several approved hazardous service types).

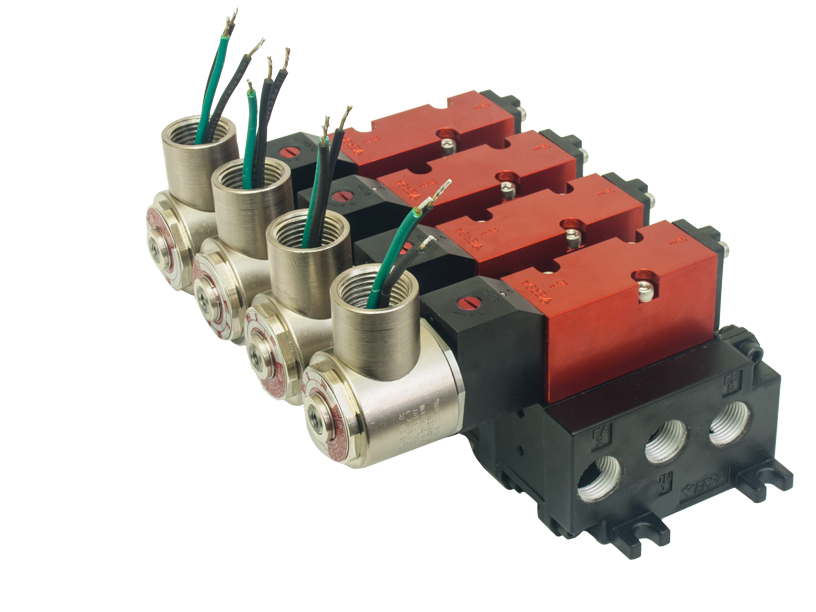

C Series Aluminum

Versa’s C-Series, C5, C7 & C9, valves are multi-purpose four-way, 5 port 2 position or 5 port 3 position, pilot operated pneumatic valves consisting of two body types, side ported and manifold mounted. Pilot supply can be either Inpilot or Expilot. A low power solenoid controls the pilot signal which provides the positive force for shifting the valve spool. Double solenoid/pilot 5/2 models feature detented offset positions. Double solenoid/pilot 5/3 models feature a spring return to the unactuated center position with all ports blocked or exhaust ports open in the center position or cylinder ports open to inlet. A balanced, packed spool is the flow controlling element of each valve. The balanced spool allows the force necessary to shift the valve to remain independent of the pressure of the medium being controlled. The use of elastomer sealing provides bubble tight operation thus enabling positive positioning of 3-position devices, and thrift of operation due to no waste of leaking air.

C-316 Stainless

The C-316 Series consists of 3-Way 3/2 and 4-Way 5/2 investment cast, 316 stainless steel valves, in three categories: Side Ported, NAMUR style direct mount and CMAP, an integral stainless steel regulator and valve. The C-316 Series is available as either a 4-way, for double acting devices or a 3-way, for spring return devices. The 3-way function can be specified as either normally closed or opened. All solenoid actuators are solenoid/pilot type, which allows the use of the smallest solenoids available resulting in low power consumption. This design also assures a positive shifting force which makes certain the valve shifts when energized and reduces the chance of coil burnout. Single solenoid spring return models utilize an air assisted spring return feature assuring a positive return. Double solenoid models are equipped with a detent that maintains the valve in the last shifted position, even in high vibration environments.

E Series

Versa’s E-Series valves are 2 port, 2 position and 3 port, 2 position direct acting pneumatic and hydraulic valves consisting of two body types, side ported and manifold mounted. E Series Side-Ported valves are individually mounted with body port sizes 1/8” NPT to 1/4” NPT. Manifold Mounting valve is direct solenoid actuated and is mounted on a manifold which can have 1 to 10 valve stations. The manifolds are provided with the threaded ports for pipe connections, which allows the valves to be easily and swiftly installed or removed without breaking any pipe connections. The manifolds also provide common ports, such as the inlet and exhaust, making only one such connection necessary per manifold.

D-316 Stainless

The Versa Products Company D-316 Series valve is a high performance, high flow, direct acting solenoid valve. Designed as a 3-way (3/2), it is a true multipurpose/universal flow, “bubble tight” valve throughout its complete operating range and cycle life. Suitable for air, natural gas and hydraulic media. High performance stainless steels make the D-316 Series an ideal choice for the harshest environments. The D-316 can be configured for full NACE compliance. Designed for ease of installation and field serviceability make the D-316 the choice for all applications.

B Series Brass

Versa B Series valves come in three distinct styles. Two-Way Types for bleeding pilots of larger valves, for bleeding cylinders or small pressure systems, operating air tools or motors, opening or closing air lines. Three-Way Types for controlling pilots or diaphragms of larger valves or small cylinders or any pressure system that is alternately pressurized and exhausted. Service: Pneumatic-vacuum to 200 psi (14 bar). Two way can be used for hydraulic pressures to 500 psi.

B-316 Stainless

The B316 Series is a complete line of compact, rugged Three-Way (3/2), side-ported valves, constructed of 316 stainless steel (conforms to NACE standard MR-01-75). They are designed for use particularly in corrosive environments and to control a variety of aggressive media as well as air. O ring packed poppets provide bubbletight sealing throughout the operating pressure range and when used to operate small volume appliances this feature conserves valuable instrument air. Actuations include solenoid/pilot (including those suitable for Ordinary, Hazardous or LOW-WATT service ), remote pressure pilot, manual, and mechanical. Many combination actuators and special function types can also be provided. Consult the factory for these items. Solenoid actuated valves can be 2-position, single or double solenoid. A manual override option is available for most types. Remote pressure pilot models can be 2-position, single or double pilot. Manually actuated valves are 2-position, push button panel mounting types and are offered with or without guarded push buttons. An optional lid knob operated type is also available. Mechanically actuated valves are 2-position and are supplied with a roller for cam interface.

NAMUR

The Versa NAMUR mount control valves are high flow, bubbletight, direct acting or solenoid/pilot operated. They are designed to mount directly to any NAMUR actuator, thus reducing actuator response time and cost of tubing, fittings, brackets, and labor. These valves are available in two materials - Aluminum and 316L stainless steel. E5 is a direct acting 3-way (3/2) solenoid valve. C5 and C316 are solenoid/pilot operated high flow, 5-port NAMUR valves. They are available as single or double solenoid 2-position (C5 - C316) and 3-position (C5) models. Single solenoid spring return models utilize an air assisted spring return feature, assuring a positive return. Double solenoid valves may be used in applications where a momentary signal is required or in a “fail in last shifted position” actuator application. A complete selection of electrical connections, area classifications, and power requirements makes the most exacting and demanding specifications or applications easy to satisfy.

Filter Regulators

The Versa Type AR-316 series of stainless steel regulators and filter regulators are designed to stand up to the harshest environments while providing highly accurate pressure regulation. Proven 316 stainless steel housing and filter assemblies along with fluorocarbon diaphragm construction make the AR-316 compatible with sour gas and adaptable to off shore environments. This quality instrument is economical to buy as well as operate, and provides extremely stable and repeatable control of gas pressure. Over ported internal flow paths helps the unit achieve high flow rates with minimal pressure drop. The ARFA stainless steel construction is ideal for sour gas and/or corrosive environments and is NACE Compliant meeting sulfide stress cracking material requirements for NACE Standard MR0175. The ARFB model, only the wetted parts are NACE compliant.

Flow Control

Versa Products Company’s Flow Control Valve (FCV) is a 316 stainless steel, NACE compliant* device combining a check and needle valve to control the speed of pneumatic actuators and cylinders. The FCV allows unrestricted full flow in one direction and adjustable flow in the reverse. Functional Description The key to Versa’s full flow is the internal design and the Versa “shuttle.” This combination provides a larger surface area and yields much higher flows than controls utilizing ball checks. When the flow is reversed, placing pressure on the “shuttle” it rapidly opens to a high flow orifice that instantly empties the volume in the line. Flow adjustment is controlled by Versa’s proven needle design from our “Bleed Control” family of products.

VMAP

The Versa Modular Air Package is a compact air management system, that will provide a full range of pneumatic accessories and functions to meet the needs of most control systems in the actuator control industry. Major components are shutoff and check valves, filter/regulators, speed controls and directional control valves. Design Benefits Versa’s VMAP simplifies the design process by combining all the components of a common circuit, into one integrated assembly. Whether a standard shutoff circuit or an intricate control system, VMAP has the features to meet the requirements of any control project. VMAP will reduce engineering, components, vendors, costs, weight and save time.

Pressure Sensor

The Versa pneumatic/hydraulic pressure sensor is a 3- way block and bleed or a 2-way bleed, 2 position valve that is operated by pressure acting on a piston opposing an adjustable spring force. It functions as either a normally closed or normally open valve, depending on which of the two “IN” ports the instrument pressure is supplied. These ports are marked as HI or LO on the valve body. The output port, marked ‘OUT’, is the same for either mode of operation. Pressure changes at the sensor port, outside the set point range, will cause the valve to operate or shift. The use of two pilot sensors mounted on a common manifold allows for a high/low pressure sensor system. One sensor functions as a low pressure cut off and the other as high pressure limit, protecting your system from pressure extremes in a complete, easy to mount package. These sensors are also known as Stick Pilots.